Replacement Pall Filter Elements

- fluid power/hydraulic filter element products

- power generation filter element products

- injection molding filter element products

- wind turbine filter element products

- racing filter elements

- oil reclamation filter element products

- oil and gas industry filter element products

- desiccant breathers

Call Us For

The SINFT® hydraulic filter elements work based on specific principles including ?

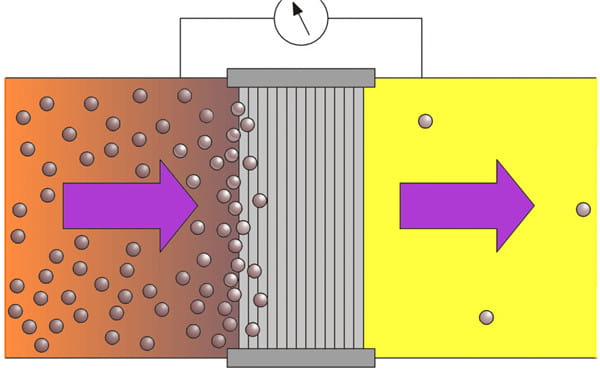

1)Pressure Filtration

The filtration principle relates to filters that are in pressure lines and deliver the ultimate protection for fittings that are downstream.You can use the pressure flow to your advantage by adding filters with ratings of around 2 micrometers or maybe less.In the case of high flow velocities, you may experience a decrease in the effectiveness of the filters. This will be as a result of disturbance to the particles within the filtration trap. Pressure filtration is the most expensive mode of filtration due to high installation and maintenance cost he high cost comes as there is a need to purchase high-quality hydraulic filters to withstand the high pressure.

2)Return Filtration

The principle of the return line for filtration follows the following philosophy: In case the reservoir, fluid, and anything that enters the reservoir have been filtered then it will continue to be clean. Fortunately, you can depend on the return line that makes it possible to force fluid through finer filters. The filters can be as fine as 10 micrometers to trap any form of contaminant in the fluid. In this case, the fluid pressure is not very high and will not interfere with the design of the filter or housing. It will, therefore, make it one of the most economical filtration processes.

3) Return-line Filtration

This is the process of filtering fluids in the hydraulic container in a totally different circuit. It relieves the filters in the main flow of heavy filtration and increases system availability. This will, in turn, lead to a decrease in the cost of operation.

4) Suction Filtration

Suction filtration is the process of separating solids from a solid, liquid mixture with an aim of retaining the solid. It uses the principle of vacuum filtration to separate the solids from the solid-fluid mixture.For instance, crystallization process depends on suction filtration to separate the crystals from the fluid.

What Types of Hydraulic Filter Elements are Manufactured by SINFT®?

The main types of hydraulic filter elements manufactured by SINFT® include:

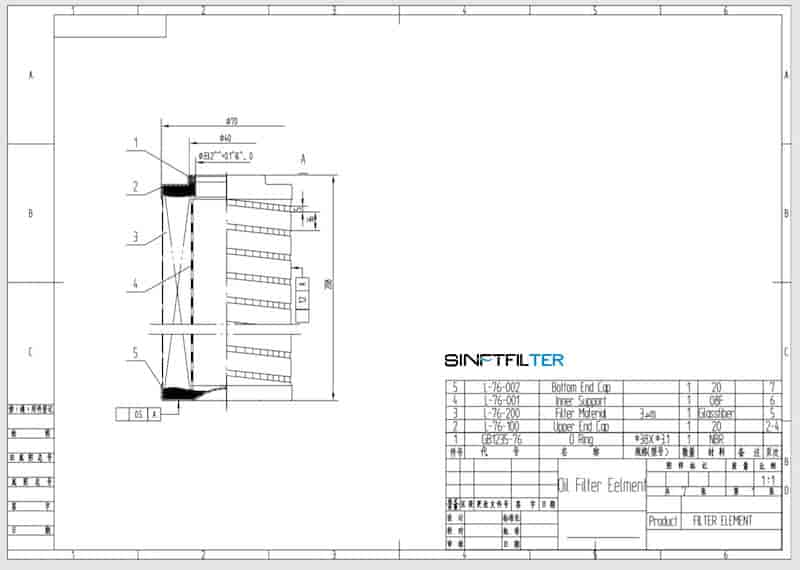

*Microglass on hydraulic filters(For SINFT filter material information, please check Download)

*Paper on hydraulic filters

*Stainless Steel wire mesh

*Here is a guide on replacement filter element

Which Filter Materials are used to Produce Hydraulic Filter Elements? Which filter media does SINFT® use?

* Microglass or Glass Fibers on Hydraulic Filters

This is a multilayer pleated structure that consists of synthetic Microglass fibers

I Epoxy adhesives to seal them from leaking

II Machining end caps to increase the integrity of the elements

III High resistance to collapse even at higher pressure.

IV Wide range of micron rating with a deep filtration.

V Combination of absorption layers that can remove both water and particles

The main advantages of using the Microglass elements include:

I It has a higher dirt holding capacity in comparison with others.

II It allows for very few element change outs as it can last longer thus saving money and time.

*Paper on Hydraulic Filters

This is a single layer structure with pleat structures made of polyester fiber and paper.

The main features include:

I High material strength and stability for flushing operations

II It is available in different micron ratings such as 5, 10, 20, and 40 micrometer micron ratings.

III The media packaging has full encapsulation in a sealant that eliminates the possibility of fluid bypass.

IV It has a wider surface area that increases high flow performance and life of the filter element.

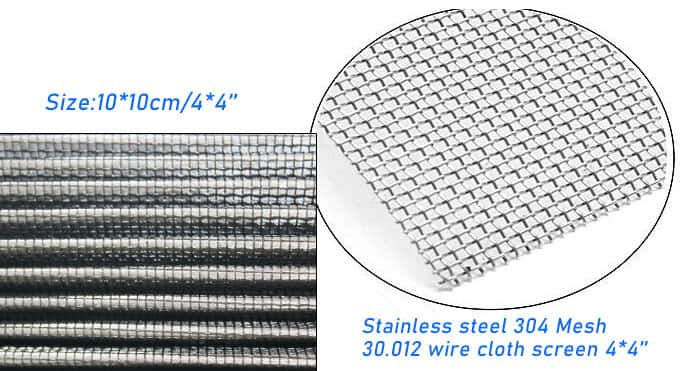

*Stainless Steel Wire Mesh

This is a single or multilayer pleated stainless steel wire mesh structure.

You can use it for surface filtration to protect the hydraulic pumps and remove particles from hydraulic fluid.

You can also get custom micron ratings according to your specifications.

It is available in different micron ratings such as 25, 40, and 80 micrometer micron ratings.

You can also get custom micron ratings according to your specifications.

The main advantage of using the stainless steel wire mesh include:

I It is easy to clean and maintain thus a longer service life.

II It is a cheaper alternative to glass fiber filter elements.

What are the Meanings of "Micron" and "Mesh" for Filtration?

The units for measuring the size of the wire mesh are in terms of the number of mesh per inch.

Implying that, if there are 5 meshes, then within one inch there are 5 gaps.

The size of mesh openings differs according to the wire diameter of the wire mesh even for the same number of mesh.

A micron, on the other hand, is a measurement unit that represents a millionth of a meter.

It is also the ability of a fluid filter to remove the contaminants depending on the size of the particles.

So, the smaller the micron rating of a particular filter, the higher the efficiency of the filter.

What is a Hydraulic Oil Filter Efficiency?

Filter efficiency is the ability of a hydraulic filter to trap contaminants within the filter element. It is a ratio of particles that a filter element cantrap over the number of particles in the upstream fluid. You can be able to determine the efficiency of the hydraulic filter just by counting the number of downstream particles. You can also tell filter efficiency depending on specific particle size ranges or the total number of particles of all sizes.

What is a hydraulic oil filter beta rating?

SINFT® hydrauclic filter element Beta rating describes the efficiency of a filter in the retention by looking at the particles retained within the filter.describes the efficiency of a filter in the retention by looking at the particles retained within the filter.

Beta rating is often a subscript number for the micron size being considered. Larger beta rating is an indication of a good hydraulic filter with a more efficient particle retention rate. For instance, β4μ means the beta rating for the filter at 4 microns. It also denotes how efficiently 4 micron particles are removed by the hydraulic filter element.

What is the Difference between Absolute and Nominal Ratings?

A measure of the pore size in the filter media is expressed as either 'Nominal' or 'Absolute'.

It also refers to the efficiency of the hydraulic filter element.

Nominal is a standard element of efficiency that depends on surface filtration.

Nominal rating is the percentage of particles of given sizes that hydraulic filters can capture.

For instance, 12 microns at 92% means the filter will remove 92% of particles of 12 microns in size.

Absolute rating, on the other hand, is a high element of efficiency that depends on a higher depth of filtration.

Absolute rating refers to the removal of all particles at a given micron size.

That is, 25-micron absolute means 100% of particles of size 25 microns or greater will be captured.

Absolute and Nominal

Beta rating describes the efficiency of a filter in the retention by looking at the particles retained within the filter.

Larger beta rating is an indication of a good hydraulic filter with a more efficient particle retention rate.

Beta rating is often a subscript number for the micron size being considered.

For instance, β4μ means the beta rating for the filter at 4 microns.

It also denotes how efficiently 4 micron particles are removed by the hydraulic filter element.

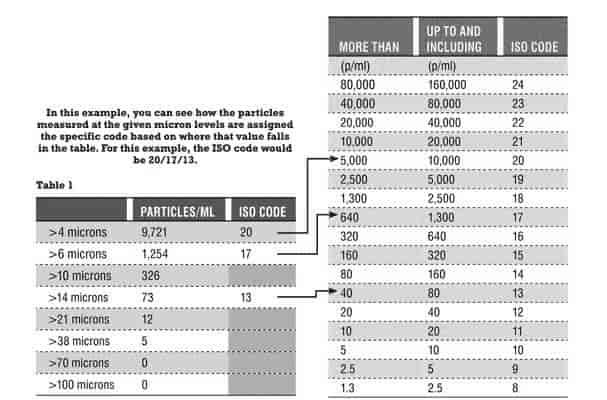

What does ISO Code Mean?

You can measure oil cleanliness in terms of ISO1046

This can be equal to or larger than 4, 6, or 14 microns in diameter.

Each ISO code represents a particular range of particle counts.

For example, ISO code 19/17/14 means that:

*Particles of diameter greater than or equal to 4μ have ISO code 19.

*Diameter that is greater than or equal to 6μ have ISO code 17.

*Diameter that is greater than or equal to 14μ have ISO code 14.