All Desiccant Breather and Part

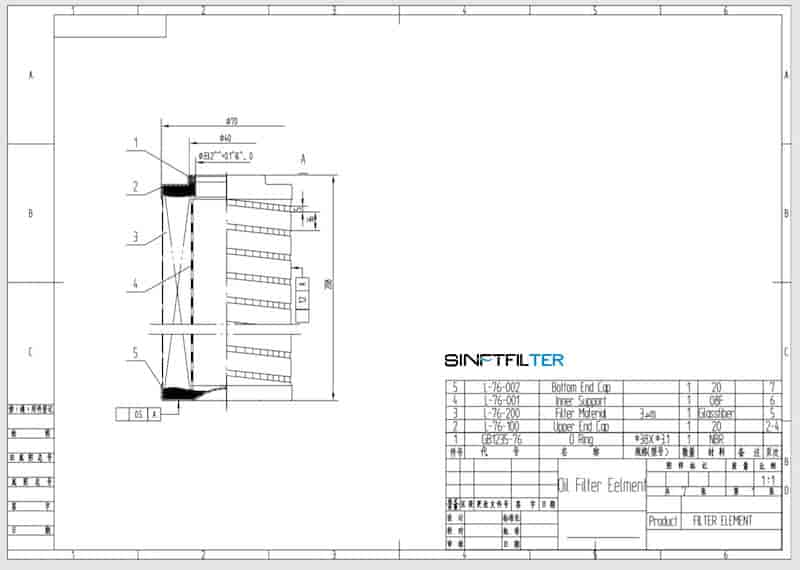

Customizable Filter Element End Cap

Optional Filter Element Interface

Sintered Stainless Steel Powder Filter Element

Specification:

- Material: titanium power particle, stainless steel powder particle.

- Filter Media: titanium powder sintered, SUS316 powder sintered.

- OD: 10mm, 20mm, 30mm, 40mm, 50mm, 60mm, 70mm, 80mm, etc.

- Thickness of wall: 1.0mm, 2.0mm, 3.0mm, 4.0mm, 5.0mm, etc.

- Length: 10", 20", 30", 40".

- Connectors: DOE, SOE, tire rod, thread (NPT, BSP, Metric) screw, flange, 220, 222, 226 (Code7).

- Working Temperature: -200 - 1000°C.

- Filter Shape: could be cartridge filters, disc filters, cup filters, cap filters, filter plate, etc.

| Sintered Titanium Powder Filter Element |

||||||

| Mode | Filtering level | Filtering precision (um) | Maximum Aperture (um) | Permeability (m3/h.m2. K pa) |

Thickness (mm) | Compressive strength (Mpa/cm2) |

| SFT-STA-1 | T9 | 0.2 | 2.5 | 1.5 | 0.6 - 10 | 3 |

| SFT-STA-2 | T8 | 0.5 | 4 | 3 | 3 | |

| SFT-STA-3 | T7 | 1 | 6 | 5 | 3 | |

| SFT-STA-4 | T6 | 2 | 10 | 15 | 3 | |

| SFT-STA-5 | T5 | 5 | 15 | 40 | 2.5 | |

| SFT-STA-6 | T4 | 10 | 30 | 120 | 2.5 | |

| SFT-STA-7 | T3 | 20 | 60 | 250 | 2.5 | |

| SFT-STA-8 | T2 | 30 | 100 | 500 | 2.5 | |

| SFT-STA-9 | T1 | 50 | 160 | 800 | 2.5 | |

| Sintered Stainless Steel Powder Filter Element |

||||||

| Model | Filtering level | Filtering precision (um) | Maximum Aperture (um) | Permeability (m3/h.m2. kPa) | Thickness (mm) | Compressive strength (Mpa/cm2) |

| SFT-SSL-1 | S9 | 0.2 | 2.5 | 1.0 | 0.6 - 10 | 3 |

| SFT-SSL-2 | S8 | 0.5 | 4 | 3 | 3 | |

| SFT-SSL-3 | S7 | 1.5 | 6 | 5 | 3 | |

| SFT-SSL-4 | S6 | 2.5 | 10 | 10 | 3 | |

| SFT-SSL-5 | S5 | 5 | 15 | 40 | 2.5 | |

| SFT-SSL-6 | S4 | 10 | 30 | 160 | 2.5 | |

| SFT-SSL-7 | S3 | 28 | 60 | 350 | 2.5 | |

| SFT-SSL-8 | S2 | 40 | 100 | 700 | 2.5 | |

| SFT-SSL-9 | S1 | 65 | 160 | 1000 | 2.5 | |

Sintered Powder Metal Sensors

Sintered Metal Sparger

Sintered Copper Filter